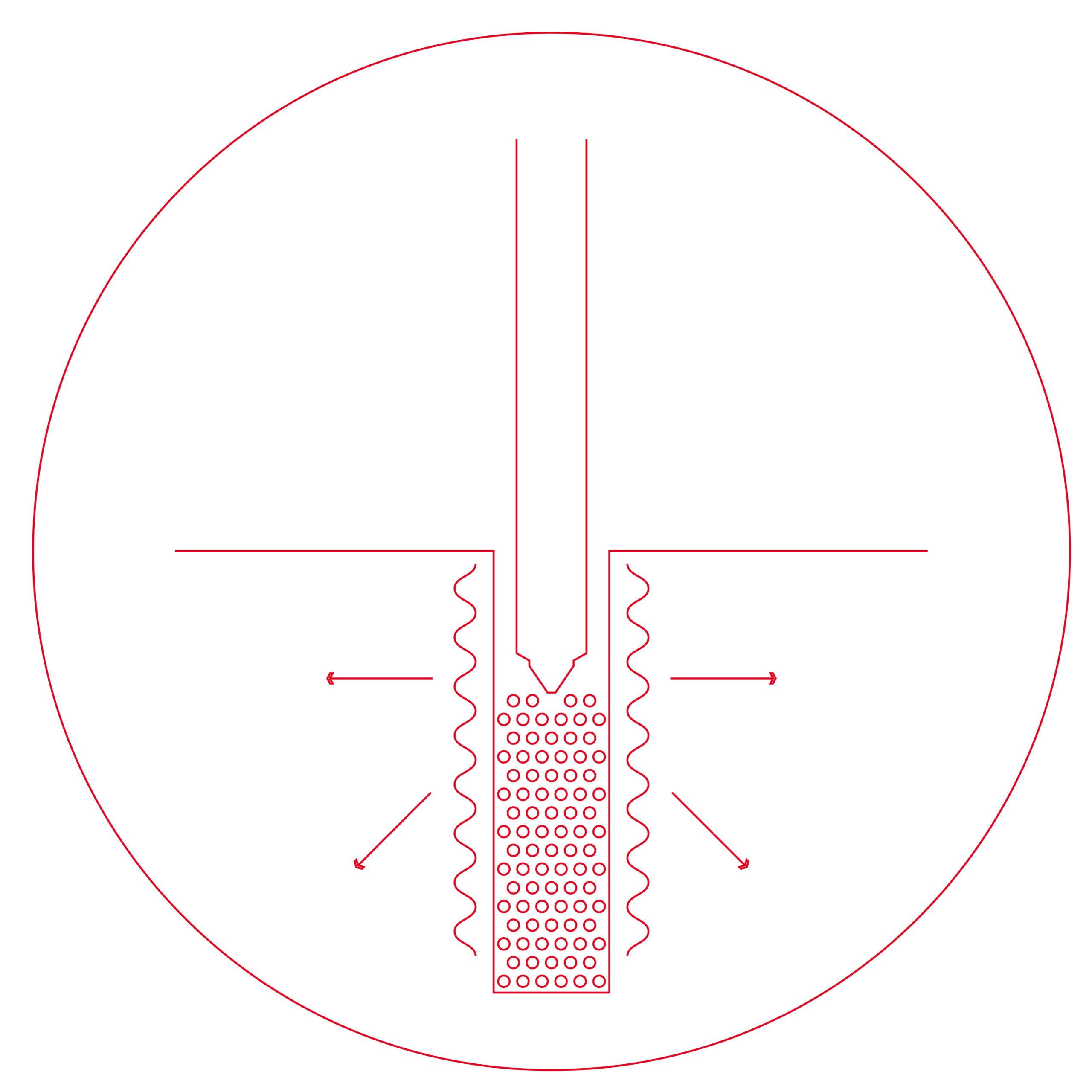

Stone Column (SC) is aggregate column formed by inserting a vibratory probe to incorporate granular material into the ground to create a vertical inclusion.

What Are Stone Columns?

Stone columns are vertical inclusions formed by compacted gravel or crushed stone. They are installed into soft, compressible soil to increase strength, reduce settlement, and improve load-bearing capacity. Each column enhances ground stability and provides vertical drainage to release pore water, accelerating consolidation.

This method is widely used for infrastructure, industrial platforms, and commercial foundations. It is a reliable alternative to deep foundations in projects with weak soil conditions.

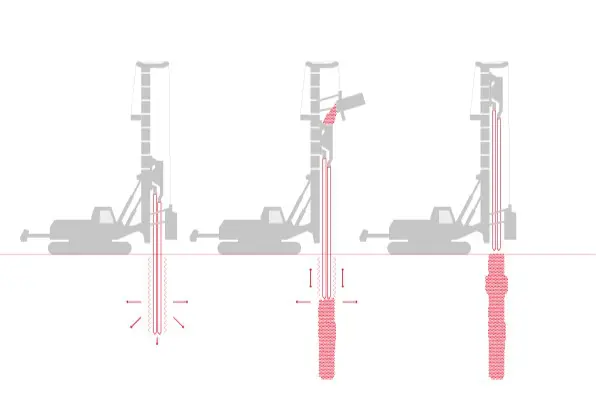

Installation Techniques

Key Advantages of the Method

Stone columns improve weak soils for construction projects. They strengthen the ground and reduce settlement. Builders can use shallow foundations instead of costly deep foundations. Stone columns offer these clear benefits.

Fast and Simple Installation

Stone columns use vibrating probes for quick placement in the ground.

This process shortens construction time. Projects finish faster compared to deep foundation methods.Lower Construction Costs

Stone columns use common materials and fast installation methods. This reduces overall project costs, saving money for builders.

Protection Against Earthquake Damage

Stone columns strengthen soil to prevent liquefaction during earthquakes. Stronger ground keeps structures safer during seismic events.

Faster Soil Improvement

Stone columns use materials that drain water easily. This drainage speeds up soil consolidation. Faster consolidation means stable soil sooner, making construction safer.

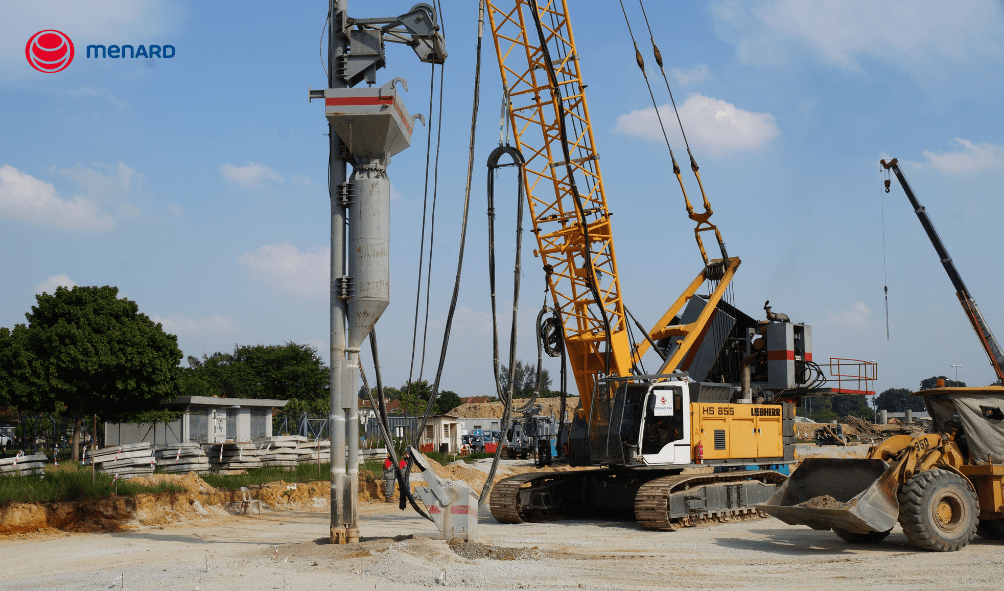

Real-time Quality Control

Menard uses modern equipment with built-in monitoring tools. These tools check installation quality in real-time. Workers can immediately correct issues, ensuring reliable results.

Where Stone Columns Are Used

Stone columns are suited for shallow to medium-depth ground improvement across various industries and infrastructure types. It is designed to strengthen compressible soils and they allow the use of shallow foundations on ground that usually call for deep foundations.

Benefits of Stone Columns

Stronger Ground Support

Stone columns reinforce compressiblesoils, distributing structural loads more evenly and reducing differential settlement. This increases safety and long-term performance.

Seismic Liquefaction Mitigation

In earthquake-prone areas, stone columns reduce liquefaction risk by densifying loose, saturated ground and improving drainage.

Cost-Effective Alternative to Deep Foundations

Compared to piling or soil replacement, stone columns are faster to install, more economical, and suitable for large-scale projects.

Environmentally Friendly

Stone columns use natural aggregate and require less excavation, lowering carbon footprint and environmental disruption. They also preserve groundwater flow.

Stone Column Specifications

- Diameter: 50 to 120 cm

- Depth: Up to 40 meters

- Spacing: Based on load requirements and soil conditions

- Installation Rate: High production with minimal noise and vibration

Why Menard Asia for Stone Column Installation

Menard Asia brings regional experience and international standards to every ground improvement project.

Field-Proven Expertise

We have delivered successful stone column solutions across Southeast Asia, including:

- Indonesia – Refinery Development Master Plan (Balikpapan), Synthetic Rubber Plant (Cilegon)

- Malaysia – West Coast Expressway, LDP Highway

- Singapore – Marina South Development

- Brunei – LNG Tank and Industrial Projects

Complete Ground Improvement Approach

We offer full-service delivery: from soil investigation and design to installation and performance monitoring. Menard Asia also integrates stone columns with other methods such as Controlled Modulus Columns (CMC) to meet project-specific needs.

Download Our Stone Column Brochure

Want technical details, case studies, and layout diagrams?

📥 Download Brochure to explore this solution.

Get a Custom Quote

Have a project in soft or reclaimed ground?

📩 Request a Quote for:

- Ground investigation and column layout design

- Equipment selection and installation method

- Timeline planning and project costing

Frequently Asked Questions

A geotechnical study identifies soil types, compressibility, and groundwater levels. If the soil is soft, silty, or loose and needs better bearing capacity, stone columns may be recommended. Menard Asia conducts soil testing and modeling to confirm feasibility.

Yes. They are highly effective in saturated soils, including coastal reclamation zones, former swamps, and low-lying areas. The columns create vertical drainage paths that improve consolidation and soil strength.

No. The process produces low vibration and limited noise. Menard Asia uses equipment designed for urban environments, ensuring minimal impact on nearby buildings, infrastructure, or operations.

Column quality is verified on-site through real-time monitoring systems attached to installation rigs. These systems continuously track boring and compaction parameters during column installation. Engineers observe this data immediately, allowing them to adjust and correct the process on the spot. This ensures consistent quality and reliable performance of the stone columns.