What is Dynamic Replacement?

Dynamic Replacement (DR) is an advanced soil improvement technique that combines elements of dynamic compaction with the installation of stone columns. It is specifically designed for highly compressible and weak soils that cannot be effectively improved through traditional dynamic compaction alone.

This method involves driving granular material deep into the ground using heavy tamping energy, forming large-diameter soil reinforcement columns ranging from 2 to 3.5 meters in diameter.

Presentation and key elements

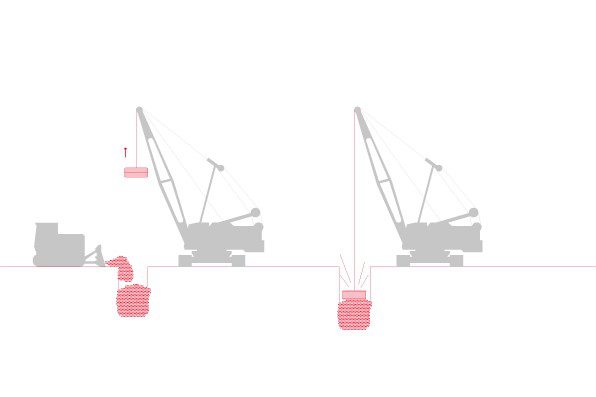

The Dynamic Replacement (DR) columns are formed by a heavy pounder with a weight ranging from 15 to 30 tons drops from a height ranging from 10 to 30 m on a 0.6 to 1.2 m thick working platform prepared on the construction site using non-cohesive soil. A single column is formed by a few series of pounding. Large diameter (1.6 to 3.0 m) columns are driven to a depth ranging from 4 to 7 m.

Following the installation of Dynamic Replacement (DR) columns, the “ironing phase” is executed where the working platform and the top layer of soil is compacted. This process is normally performed by using a flat-shaped pounder with a square base. Single pounds are performed side by side at a distance equal to the external dimension of the pounder base so that the whole improved surface area is covered. Finally, classic compaction with the use of heavy vibratory rollers is conducted to complete the soil treatment.

Dynamic Replacement (DR) columns can act as piles with an extended head for stabilisation of road or rail embankments where the columns improve the stability and increase the safety factor of the embankment. These columns are also successfully applied to reduce the foundation settlement of commercial and industrial buildings and to stabilise landfills.

Dynamic Replacement (DR) columns can be constructed both in loose non-cohesive and firm soils, soft cohesive soils as well as in organic deposits. Natural aggregates, concrete rubble, crushed asphalt and construction rubble can be used to form the Dynamic Replacement (DR) columns

The Dynamic Replacement Process

Tamping

Heavy pounders weighing between 10 and 35 tons are dropped from heights of 10 to 30 meters onto the ground surface. This energy drives granular material down into the weak soil, forming a dynamic replacement column.

Print Backfilling

The granular material is progressively added between each tamping phase, allowing the column to be constructed to the required depth and diameter. The process ensures the material fills any voids and compacts into a dense, load-bearing column.

Pre-excavation (if necessary)

In cases where there are dense or compact surface layers, pre-excavation might be required to reach the desired depth. The excavation is then partially backfilled with granular material, which is driven further into the soft soil by the tamping energy.

Material Selection

Granular fill material (generally up to 400 mm in size) with low fine content (less than 15%) is used for dynamic replacement. Common materials include crushed stone, recycled demolition debris (excluding wood, metal, and plaster), and other locally available granular backfill options.

Benefits and Applications

Benefits of Dynamic Replacement

1. Enhanced Load-Bearing Capacity

Dynamic replacement significantly improves soil strength, allowing columns to support loads of up to 150 tons (≈1450 kN). This makes it suitable for infrastructure projects with substantial loading requirements.

2. Efficient and High Production Rates

The process offers rapid ground improvement, making it an efficient solution for large-scale projects. Compared to other methods, it delivers faster construction times and reduces project costs.

3. Sustainability and Environmental Benefits

The technique minimizes the need for extensive soil excavation and disposal, resulting in a reduced environmental impact. It also allows for the use of recycled materials, such as demolition debris, making it a more sustainable option.

4. Versatility

Dynamic replacement is effective in improving a wide variety of soil types, including highly organic soils like peat, which are typically challenging for other ground improvement techniques.

5. Increased Soil Consolidation and Stability:

The process enhances the drainage of soft soils, contributing to consolidation over time. This makes it ideal for areas where long-term soil stability is crucial, such as under embankments or slopes.

Applications of Dynamic Replacement

Dynamic replacement is suitable for a broad range of construction and infrastructure projects, including:

1. Logistics Platforms & Industrial Buildings

Ensures the foundation stability needed for heavy machinery and storage facilities.

2. Storage Tanks

Provides reliable ground improvement for large tanks requiring high load-bearing capacities.

3. Harbour Areas

Suitable for port development projects where soft soils are prevalent.

4. Airports

Ideal for runways, taxiways, and other airport infrastructure requiring stable ground.

5. Roads & Railways

Enhances ground stability for transport infrastructure, improving the lifespan of these constructions.

6. Earth Banks & Embankments

Improves the factor of safety against slope failure, making it ideal for earthwork projects.

Why Choose Menard Asia for Dynamic Replacement Services

Expertise and Experience

With decades of experience in ground improvement projects, Menard Asia is a leading authority in dynamic replacement. Our team comprises skilled engineers and technicians who ensure the success of each project.

Advanced Technology and Equipment

We utilize state-of-the-art tamping equipment and innovative techniques to maximize the efficiency and effectiveness of dynamic replacement.

Proven Track Record

Menard Asia has an extensive portfolio of successful projects across various industries, demonstrating our capability to deliver exceptional results, even in challenging soil conditions.

Tailored Solutions

Every project is unique, and Menard Asia provides customized dynamic replacement solutions tailored to each client’s requirements, ensuring optimal outcomes.

Download Our Brochure

FAQs About DR

If the ground cannot be dynamically compacted directly due to high fines content within the soil, a granular material must be added. This technique is well suited to highly compressible and weak soils and can be applied to structures with high loading (high embankment, storage tanks, etc.). It improves the bearing capacity of the poor soils and the subsequent reduction and control of total and differential settlements. An additional benefit is that dynamic replacement pillars allow for rapid drainage of the ground.

The technique can be carried out with or without pre-excavation!

While dynamic compaction focuses on densifying the existing soil using impact energy, dynamic replacement goes a step further by introducing granular material into the weak soil to create reinforced columns.

Dynamic replacement is highly effective for treating soft soils, such as peat or organic clay, where traditional dynamic compaction might be insufficient.

Contact Us for Dynamic Replacement Services

Ready to start your ground improvement project? Contact Menard Asia today for a customized quote.

Our projects

Philippines | Kalayaan 2 Wind Power Project

Bangladesh | Industrial Facility in Trishal, Mymensingh

Cambodia | Bassac Lane Restaurant, Phnom Penh

Cambodia | Sihanoukville Port Expansion with Vibro Compaction

Cambodia | Office Building in Bavet