What is Dynamic Compaction?

Invented by Louis Ménard in the 1960s, Dynamic Compaction is a leading soil improvement technique that has already been used on several thousand structures around the world.

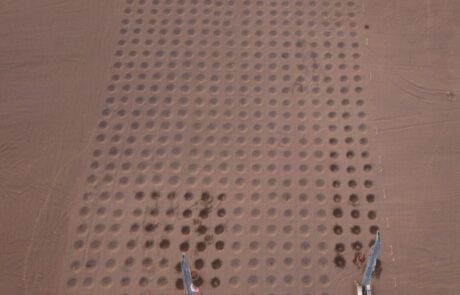

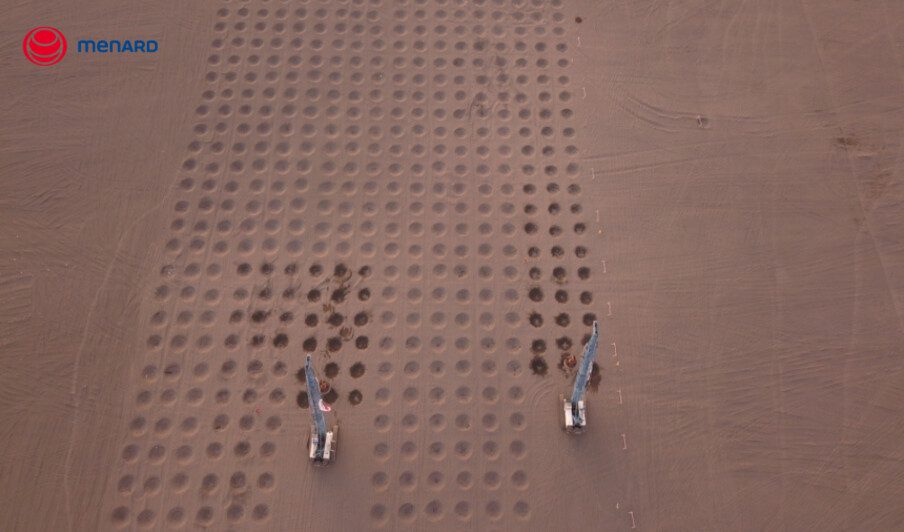

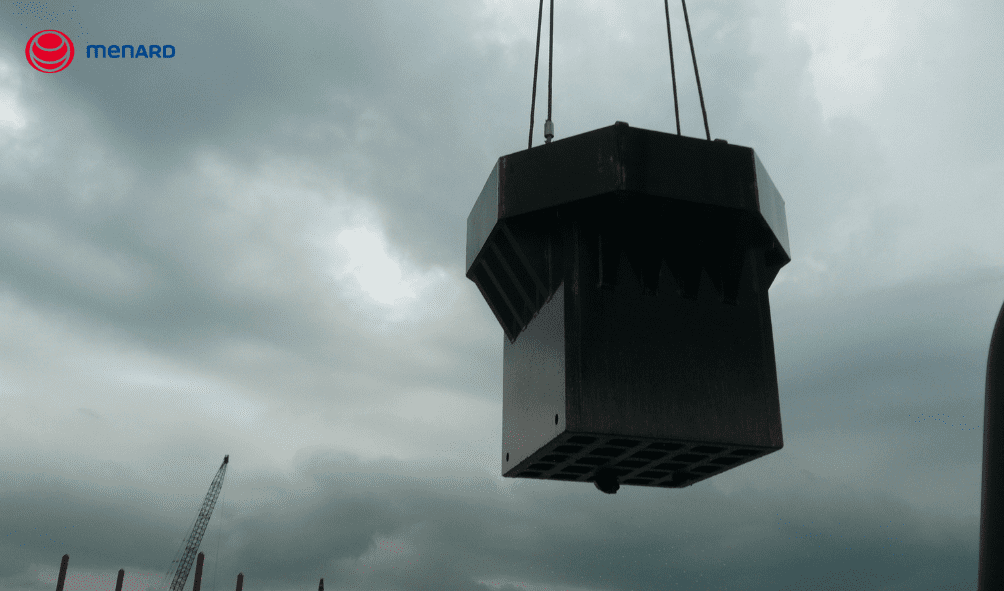

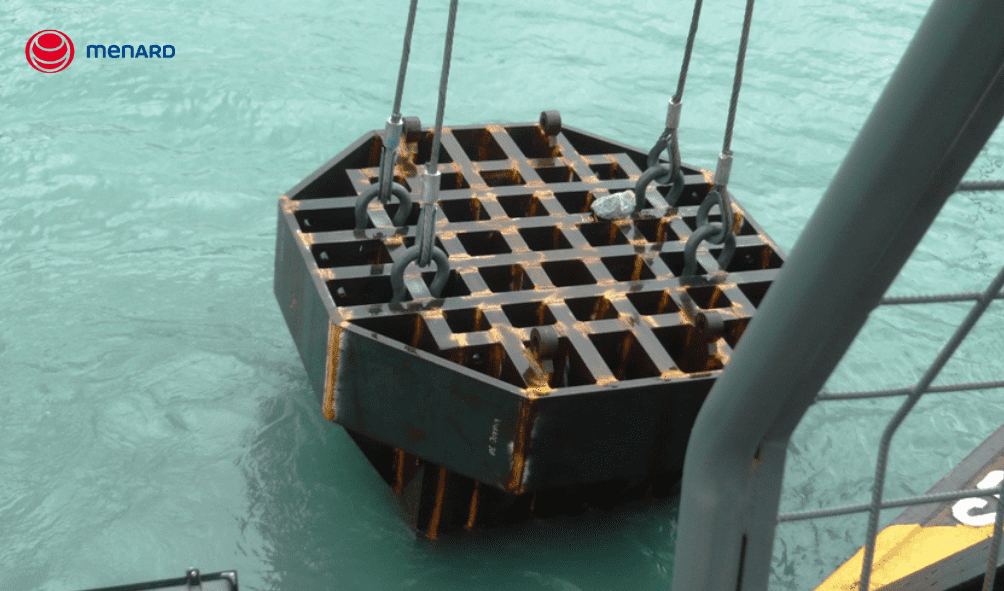

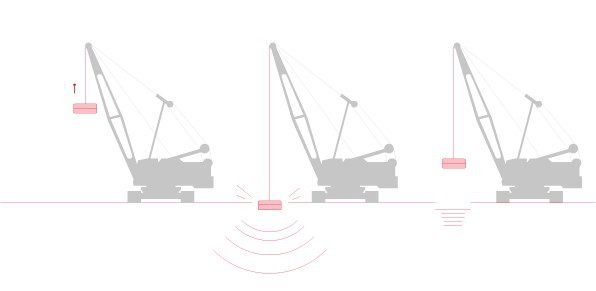

Dynamic Compaction is a method used to enhance the mechanical characteristics of soil by densifying it at depth using a mass that impacts the soil surface. This technique is particularly efficient for improving loose, low-bearing soils, such as sand, without the need for adding any extra materials, making it an environmentally friendly option.

The Dynamic Compaction technology, also known as dynamic consolidation, is a technology invented and developed by Menard. This technology was extensively tested and optimised hence its safe and economic application today.

Dynamic Compaction Process

Applications of Dynamic Compaction

Menard Quality Assurance

Menard Asia ensures the effectiveness of dynamic compaction through continuous monitoring and testing:

- Pre-construction: Test boards are set up to analyze soil conditions.

- During construction: Inspections are conducted to ensure compaction efficiency.

- Post-construction: Geotechnical tests such as Menard pressiometer tests or plate loading tests are carried out to verify the results.

Additionally, Menard works on measuring and controlling vibrations generated by the technique, especially in urban areas to ensure minimal disruption to nearby structures.

Why Menard Asia for Dynamic Compaction?

Expertise and Experience

Menard Asia has decades of experience in dynamic compaction, offering unparalleled expertise in executing this technique effectively and efficiently. Our team has completed thousands of projects worldwide, making us a trusted partner for ground improvement solutions

Our Dynamic Compaction Project

FAQs about Dynamic Compaction Services

Contact Us

Request a Quote and Get in Touch!

Reach out to our team for a customized quote tailored to your project needs and discuss your ground improvement requirements.