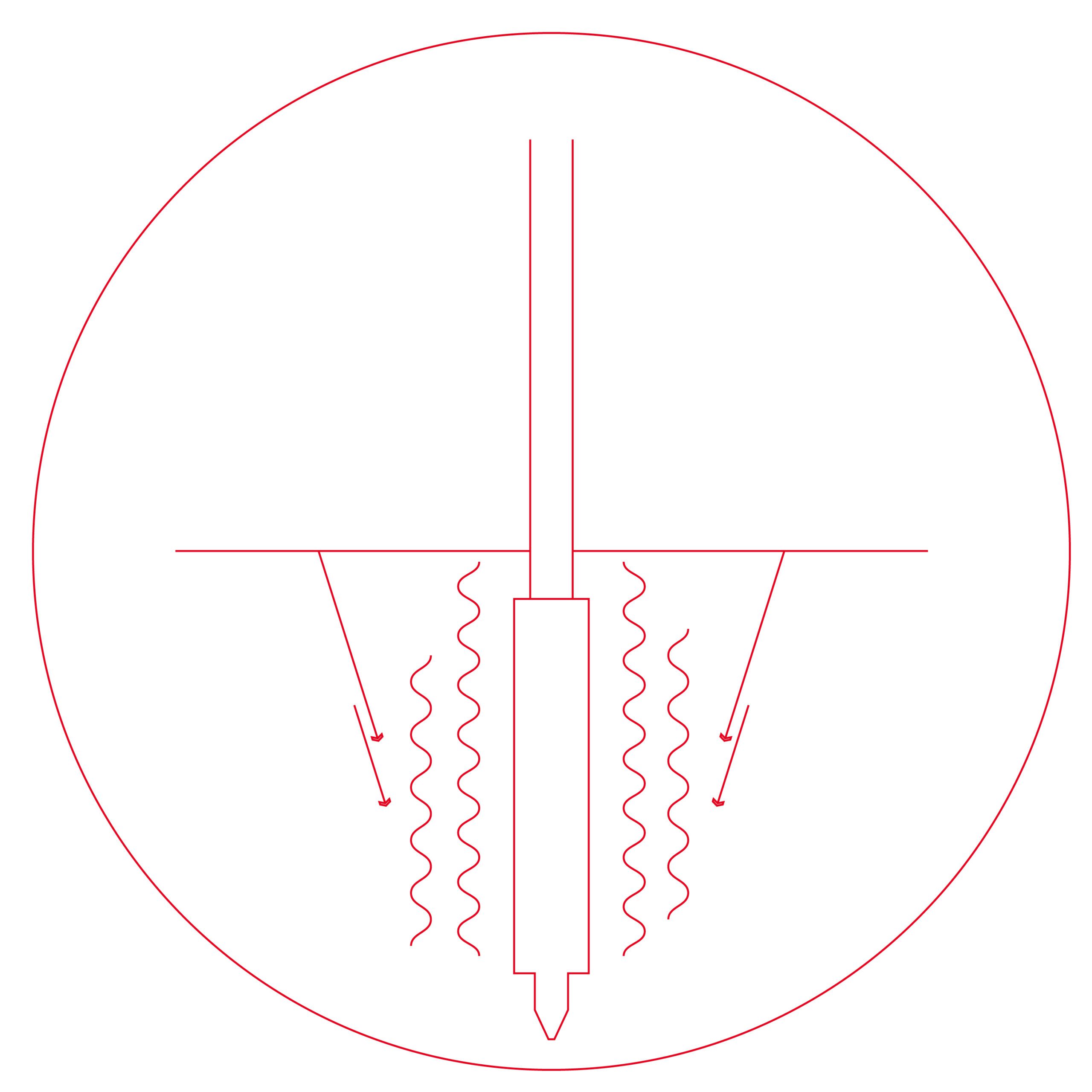

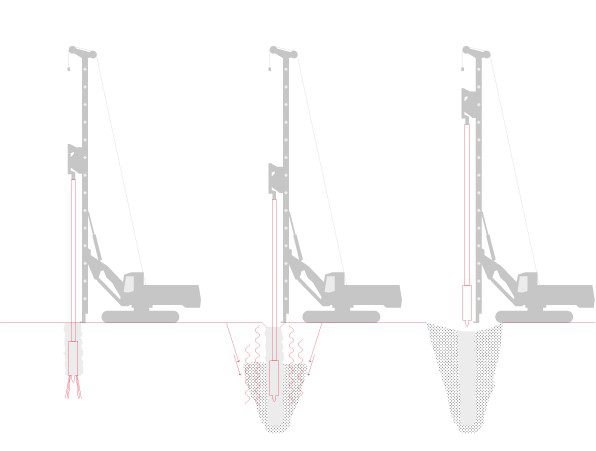

Vibro compaction (VC) improves granular soils by rearranging the grain distribution pattern using cyclic vibrations via vibroflot to compact the soils.

Vibroflotation technology or vibro compaction method is used to compact loose granular soils to increase bearing capacity; to reduce settlement; and to reduce the potential of liquefaction.

What is Vibrocompaction?

How Vibrocompaction Works

Applications of Vibrocompaction

Vibro Compaction can be used for the foundation of various facilities such as parking lots, airport runways, roads and structures on areas reclaimed from the sea.

It is well suited for the foundation of facilities with uniformly distributed pressure onto the subsoil. It significantly reduces the settlement and leads to the unification of the foundation conditions (i.e., minimise the differential settlement).

1. Land Reclamation

Used extensively to stabilize newly reclaimed land in coastal areas, ensuring suitability for future infrastructure, buildings, or industrial development.

2. Transportation Infrastructure

Improves foundation conditions for roads, bridges, highways, railways, and airport runways. It supports embankments and minimizes differential settlement along long linear structures.

3. Industrial Platforms

Prepares large sites such as storage yards, container terminals, and logistics hubs. Ensures ground performance under uniformly distributed loads from tanks and heavy equipment.

4. Marine and Coastal Structures

Reinforces seabed and coastal soils beneath ports, breakwaters, and quay walls, allowing safe construction even in soft, saturated conditions.

Benefits of Vibrocompaction

Why Choose Menard Asia for Vibrocompaction

1. Regional Expertise and Proven Results

2. Integrated Ground Improvement Solutions

We offer vibrocompaction as a standalone solution or in combination with other ground improvement solutions to optimize performance across varied soil conditions.

3. Complete Support from Start to Finish

Menard Asia handles every stage:

- Soil investigation

- Compaction grid design and modeling

- Equipment mobilization and installation

- Quality monitoring

Download the Vibrocompaction Brochure

Looking for detailed specs, project examples, or compaction design methods?

📥 Download Our Brochure to learn how vibrocompaction can accelerate your project while improving ground performance.

Request a Quote or Technical Review

Planning a project with sandy, loose soils?

📩 Request a Quote to receive:

- Site-specific feasibility review

- Recommended compaction method and design

- Equipment and timeline planning

- Transparent cost breakdown