What is Rapid Impact Compaction?

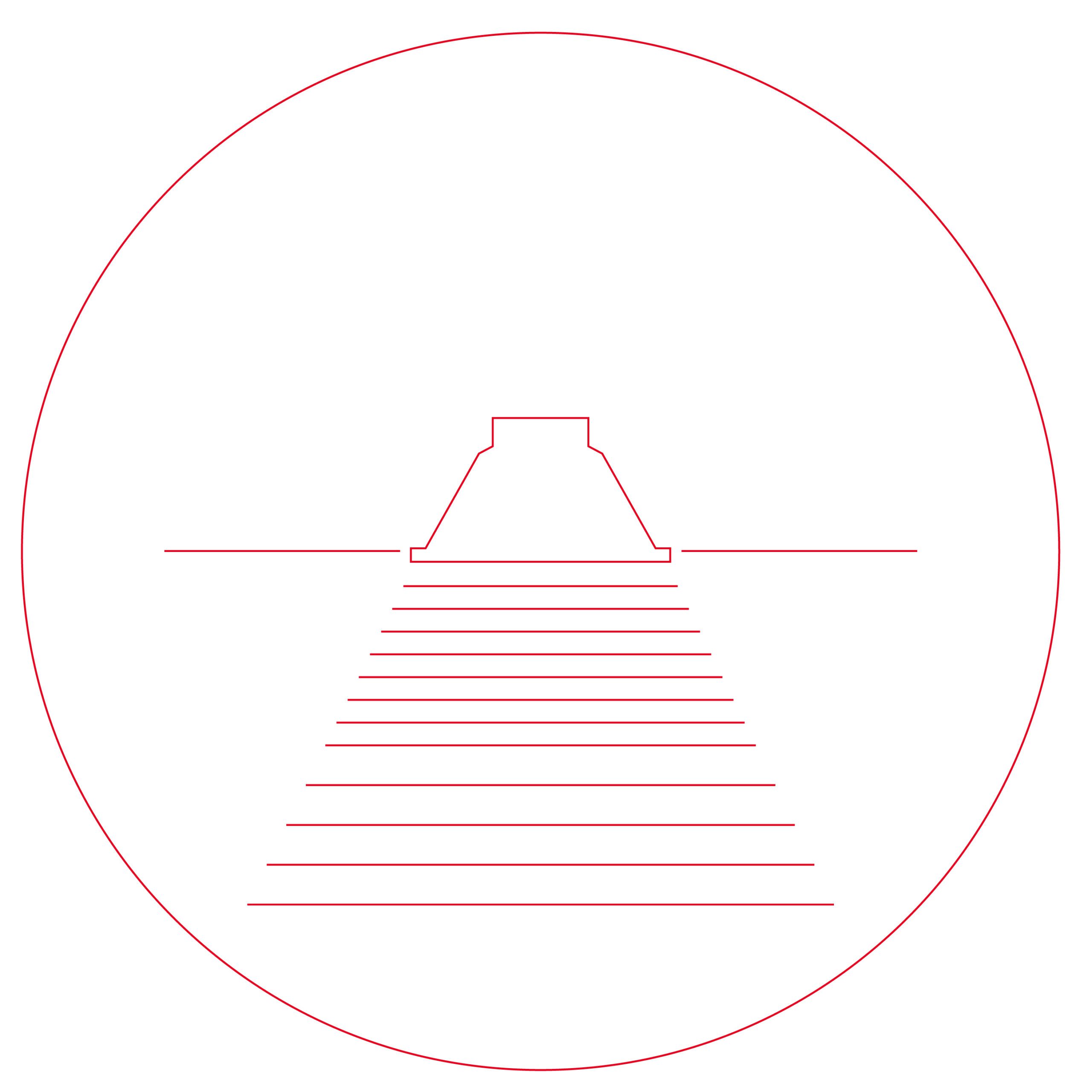

Rapid Impact Compaction (RIC) is a dynamic soil improvement method that densifies surface layers of soils (usually 5 to 7 meters) using repeated vertical energy impacts.

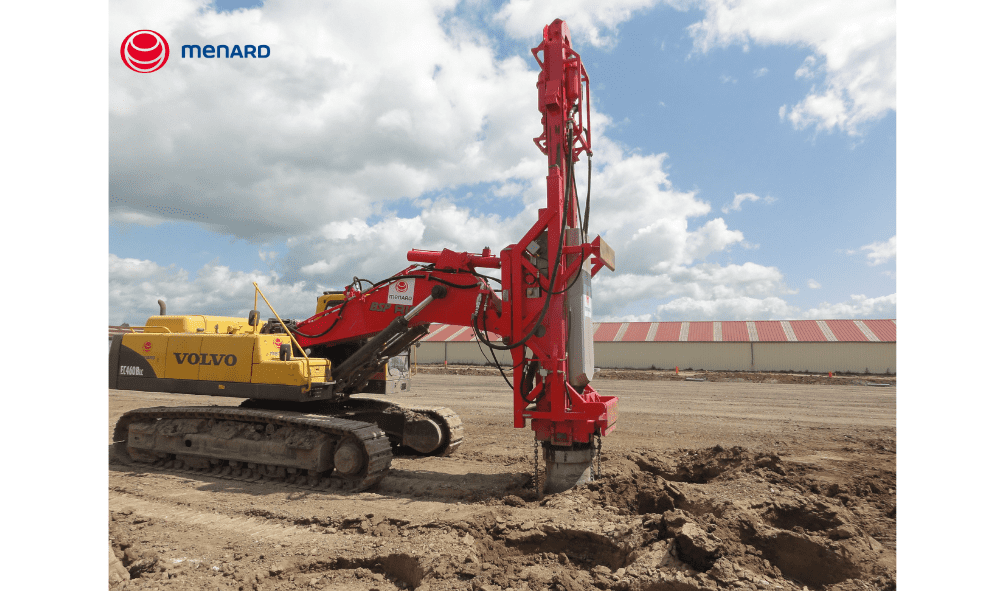

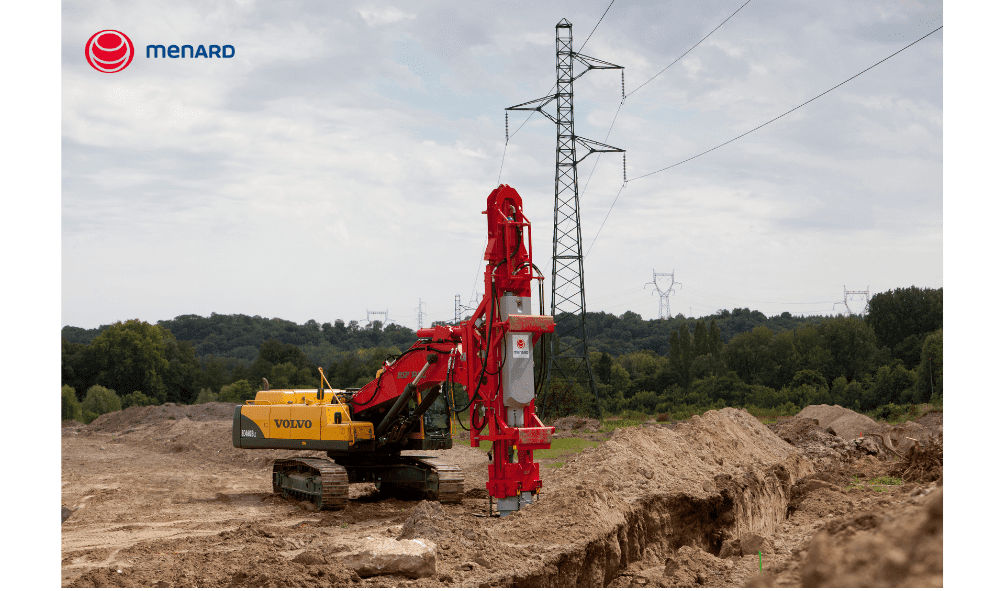

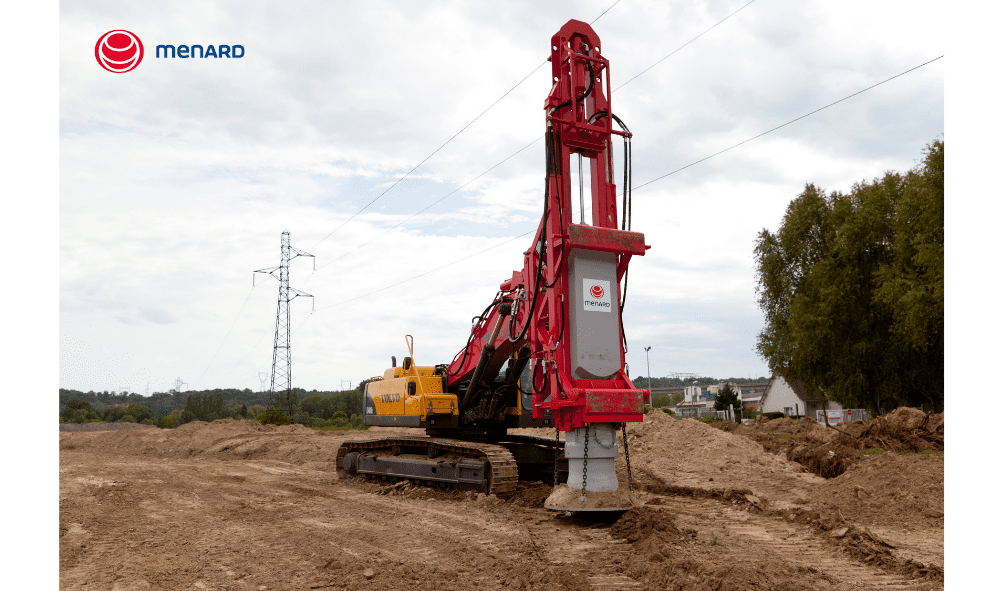

The process uses a hydraulic hammer, mounted on a tracked excavator, that strikes a large circular foot at high frequency. Each impact forces the soil into a denser state thereby increasing its load-bearing capacity and reducing future settlement.

Rapid Impact Compaction (RIC) is fast, efficient, and well-suited for shallow improvement depths.

How Rapid Impact Compaction (RIC) Works

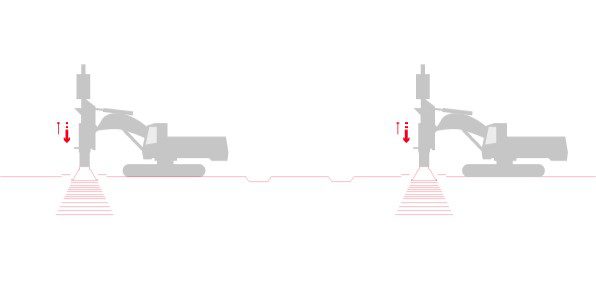

The Rapid Impact Compaction for the soil improvement uses a hydraulic hammer mounted on an excavator. The hammer with a weight ranging from 5 up to 12 tons is dropped freely from a height of 1.2 m on a large circular foot. Impacts repeated at a rate ranging from 40 up to 60 blows per minute plunge the steel foot creating a crater.

The control system installed in the operator’s cab allows for controlling the compaction process and recording the parameters such as impact energy or foot penetration. It can also be used to change the height from which the hammer is dropped.

The compaction in the RIC technology is usually preceded by creating a test plot where the compaction is performed for various spacing and rates of blows.

Then, the local compaction of the improved soil is tested and the optimal grid spacing and the number of blows per one point is determined. Depending on the soils, the number of blows varies between 10 and 40 per one point.

Applications of Rapid Impact Compaction

The Rapid Impact Compaction technology works very well for all kinds of non-cohesive soils, especially for the compaction of gravels and sands. It can also be used on reclaimed areas where anthropogenic soils and uncompacted fills occur

Most often, the Rapid Compaction Impact (RIC) technology is used for the construction of enclosed buildings under the foundation slabs/floors of industrial and commercial halls and under heavy surfaces of warehouses, tanks; for the construction of infrastructure: all types of roads and highways, under the road and rail embankments and often as the improvement of the base for parking lots and airport runways.

A great advantage of the RIC method is its mobility and relatively small size of the equipment unit which allows for carrying out the works in areas with difficult access.

Key Advantages of Rapid Impact Compaction

Fast and Efficient Execution

RIC enables the treatment of large areas quickly, with dozens of impact points compacted per hour. Its high production rate significantly reduces site preparation time and accelerates project delivery.

Versatile Across Soil Conditions

Rapid Impact Compaction is effective in all types of compressible soils, including reclaimed and variable fill zones where traditional methods may underperform.

Compact Equipment for Confined Sites

Mounted on a tracked excavator, the RIC system (M-RIC®) is easy to mobilize and highly maneuverable—making it ideal for confined areas, including work within existing buildings or infrastructure.

Minimal Environmental Impact

RIC involves no addition of materials. Additionally, by compacting in-situ soils, RIC eliminates the need for excavation, trucking, or importing fill thus making the process produces minimal waste.

Why Menard Asia for Rapid Impact Compaction Solution?

- Field-Tested in Southeast Asia

Menard has successfully delivered Rapid Impact Compaction projects worldwide. Backed by Menard’s global network,we provide solutions adapted to diverse soil types and geotechnical challenges in Asia.

- Integrated Design and Delivery

From site evaluation to execution, Menard Asia manages the entire Rapid Impact Compaction process:

— Soil investigation

— Grid design and energy calibration

— Equipment mobilization and compaction

— Real-time monitoring and quality control

— Post-treatment testing and reporting

Download the RIC Brochure

Want technical specs and method insights?

📥 Download Menard Asia’s RIC Brochure to explore.

Request a Site Evaluation or Quote

Need ground improvement for your next project?

📩 Request a Quote to get:

- Test plot recommendations

- Compaction design and energy plan

- Scheduling, equipment, and costing

- Full support from Menard Asia’s geotechnical team

Frequently Asked Questions (FAQ)

Rapid Impact Compaction is used to compact loose granular soils or waste material ranging from 3 to 7 m to increase bearing capacity and reduce settlement. It is often used in low headroom sites or when the minimal vibrations are allowed.

The Rapid Impact Compaction technology works very well for all kinds of non-cohesive soils, especially for the compaction of gravels and sands. It can also be used on reclaimed areas where anthropogenic soils and uncompacted fills occur.

Rapid Impact Compaction is faster, produces less waste, and uses in-place soils. It avoids the costs of excavation, soil removal, or deep foundations. This makes it ideal for large, shallow improvement areas like parking lots or industrial platforms.

Our projects

Laos | Truong Son Wind Power Plantirfan2025-09-29T15:15:07+07:00

Philippines | Kalayaan 2 Wind Power Projectirfan2025-06-02T15:35:49+07:00

Bangladesh | Industrial Facility in Trishal, Mymensinghirfan2025-05-31T08:52:02+07:00

Cambodia | Bassac Lane Restaurant, Phnom Penhirfan2025-05-31T08:56:27+07:00

Cambodia | Sihanoukville Port Expansion with Vibro Compactionirfan2025-05-20T09:01:34+07:00

Cambodia | Office Building in Bavetirfan2025-05-16T09:20:40+07:00