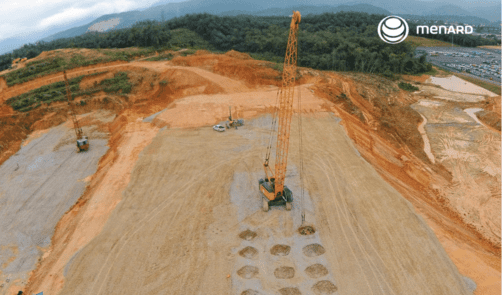

Ground Improvement Works for an Industrial Complex in Serendah – Malaysia

About Ground Improvement Technique

Menard Asia is using two ground improvement techniques for this project, which are Dynamic Replacement and Dynamic Compaction.

Dynamic Replacement

The Dynamic Replacement (DR) columns are formed by a heavy pounder with a weight ranging from 15 to 30 tons drops from a height ranging from 10 to 30 m on a 0.6 to 1.2 m thick working platform prepared on the construction site using non-cohesive soil. A single column is formed by a few series of pounding. Large diameter (1.6 to 3.0 m) columns are driven to a depth ranging from 4 to 7 m.

Dynamic Compaction

The basic principle behind the Dynamic Compaction (DC) technique consists in the transmission of high energy waves in order to improve weak subsoil. As a result of the impact the soil is compacted depending on its condition, structure and depth. The energy is transferred to the subsoil by multiple impacts with properly shaped weight (normally steel pounder) with a weight ranging from 10 to 40 tons free falling from a height ranging from 5 to 40 m.

#GroundImprovement for Serendah Industrial Complex

In 2016, Menard Asia has completed the ground improvement works for an industrial complex in Serendah, Selangor, Malaysia. Menard Asia’s solution for this project was Dynamic Compactionand Dynamic Replacement to treat an area of 82,650 m². The ground improvement works is adopted to accelerate the filling of a valley for the construction of an industrial complex. Furthermore, this industrial building is a place to manufacture the fan cover of an airplane engine.

Menard Asia is a specialist geotechnical EPC contractor offering ground improvement and remediation works in Malaysia, Indonesia, Vietnam, Singapore, Bangladesh, Cambodia, Philippines, Thailand, and other South-East Asia Countries.