Menard Vacuum Consolidation developed by Menard in 1980s enable effective use of vacuum pumps to accelerate weak soil compression. It is an efficient time-saving consolidation method; loading and construction can proceed as early as two weeks after vacuum pumping.

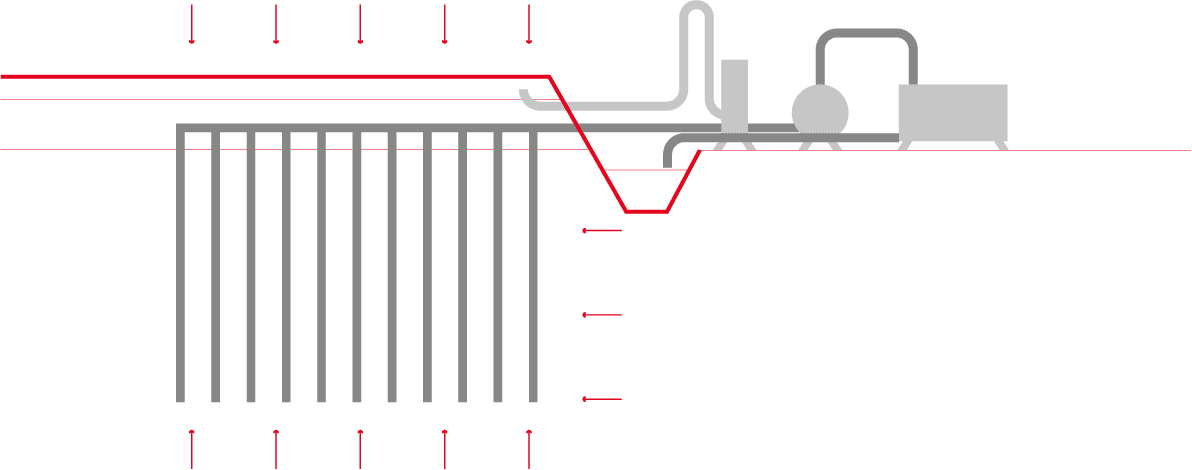

Presentation and key elements

Menard Vacuum Consolidation (MVC) involves the installation of both vertical and horizontal vacuum transmission pipes and peripheral trenches. An airtight impervious membrane is then installed on the ground surface and sealed in the peripheral trenches.

Menard Vacuum Pumps are then connected to the system to remove the air below the membrane. This results in the creation of a vacuum under this membrane. The difference of pressure at the membrane interface creates a gradient resulting in the application of a pressure almost equivalent to the atmospheric pressure on the ground below the membrane.

This loading process creates an isotropic state of stress in the soils under the membrane, accelerating the consolidation in the soil mass in a very short time and reducing the need for placing potentially unstable surcharge fill.

The Menard Vacuum Consolidation technology has a wide range of applications from the construction of roads and highways, areas designated for different types of tanks (for liquids, Gas, granular materials) to large spatial areas such as airport terminals, harbour container terminals or power plant.

This method is suitable for organic soils with high moisture content and existing in large areas. It is also suitable for soft cohesive soils with a thickness of more than 30 m. Maximum loads transferred to the consolidated soil depend directly on the type, degree of the consolidation and the nature of the structure.

Menard Vacuum™ is a technique created and developed by Menard to control long term residual settlement in saturated cohesive compressible soils. The drainage of water and soil consolidation can be a very lengthy process, Menard Vacuum™ accelerates the process so you can safely develop your projects.

Our projects

Cambodia | Bakheng Water Production Facilities at Phase 3

Cambodia | LFRD School Building

Cambodia | Luang Mae Hospital Bunker Project

Cambodia | Cargo Terminal Building for Techo International Airport – CMC

Cambodia | Data Center Building – CMC