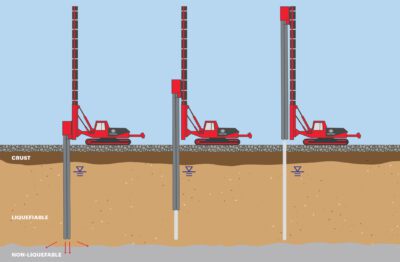

Earthquake Drains (EQ Drains) are a vital technique designed to mitigate the effects of liquefaction during seismic events. Liquefaction occurs when seismic activity increases pore water pressures within granular soils, such as sands, leading to loss of shear strength, lateral spreading, excessive settlement, and potential bearing capacity failures.

Presentation and key elements

Advantages of Earthquake Drains

- Simple Installation: The process is straightforward and can be modified to accommodate sensitive sites.

- Cost-Effective: Compared to other ground improvement methods requiring expensive materials like stone and cement, EQ Drains are economical and environmentally sustainable.

- Minimal Spoils Generation: When installed using driven displacement methods, minimal spoils are produced, reducing the environmental impact.

- Densification of Surrounding Soils: The vibratory installation method can also densify surrounding soils, particularly sands with low fines content.

- Flexibility in Techniques: Installation techniques can be adjusted to protect vibration-sensitive structures and environments.