Prefabricated Vertical Drain technology is closely related to the consolidation process. Often applied with the surcharge fill, it is one of the most reliable and certainly the most economical ground improvement method to treat soft cohesive soils.

What Are Prefabricated Vertical Drains (PVD)?

How Prefabricated Vertical Drains Work

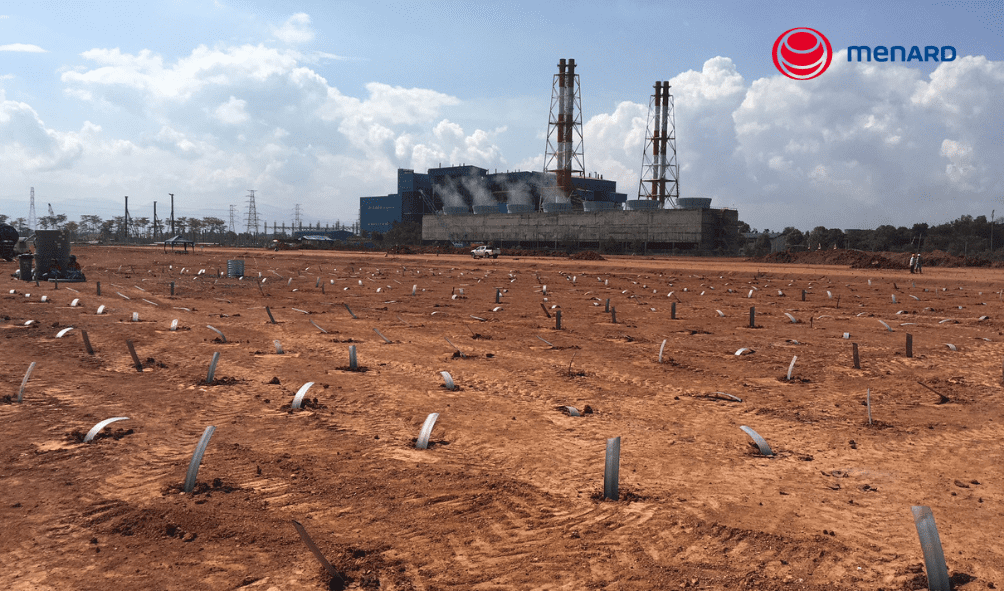

Prefabricated Vertical Drains are often combined with preloading or surcharge fill to accelerate primary consolidation and induce secondary (creep) settlement. When installed in a grid pattern, the vertical drains increase the soil’s apparent mass permeability, allowing trapped pore water to escape faster under loading.

It is used in combination with temporary surcharge fill to expedite the primary consolidation as well as induce several decades of secondary consolidation (creep) settlement. The main geotechnical parameters (settlements, pore water pressure, horizontal displacements) are monitored via appropriate instruments throughout the consolidation period to validate the design and ensure safe phasing for the construction of the embankment.

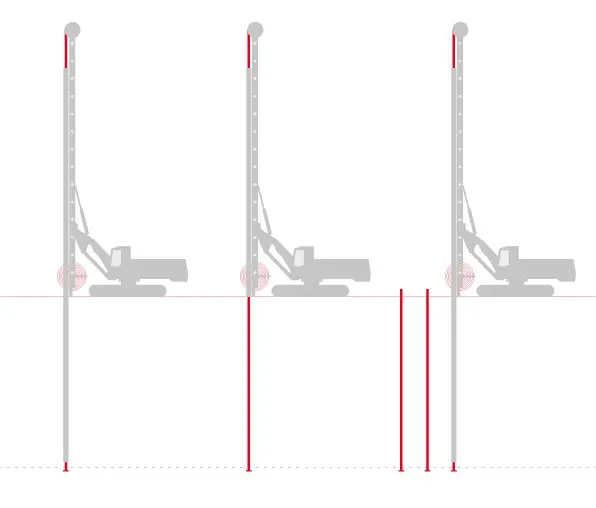

Installation Process

- 1

Site Preparation

The site is cleared, leveled, and mapped for drain layout based on geotechnical design. - 2

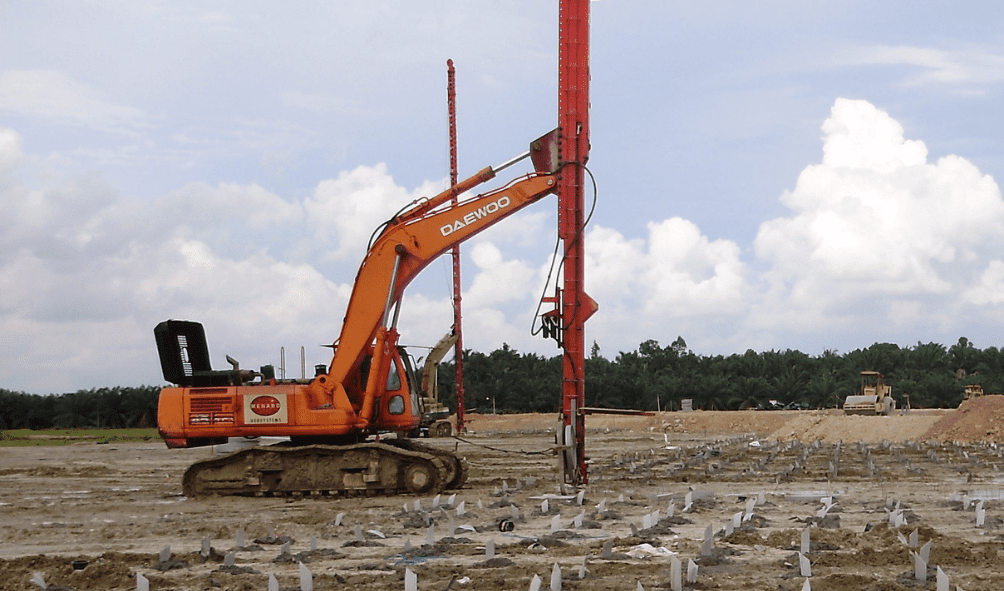

Mandrel Insertion

A steel mandrel attached to an excavator or hydraulic rig pushes the PVD into the soil to the target depth, often up to 50 meters. - 3

Anchor Deployment

The PVD is anchored at the bottom to prevent displacement during withdrawal. - 4

Mandrel Withdrawal

The mandrel is retracted, leaving the PVD embedded vertically in place. - 5

Surcharge Placement

A temporary load, typically soil or sand, is placed on top of the ground to accelerate consolidation. - 6Monitoring

Instruments monitor settlements, pore water pressure, and horizontal displacements throughout the consolidation period to verify performance and ensure construction safety.

PVD Animation

Applications of PVD in Infrastructure and Development

PVDs are essential in projects where soft, compressible soils pose a risk to stability and schedule. They are used in:

Benefits of Prefabricated Vertical Drains

Why Choose Prefabricated Vertical Drain by Menard Asia?

Menard Asia delivers proven PVD solutions supported by deep regional expertise and cutting-edge equipment.

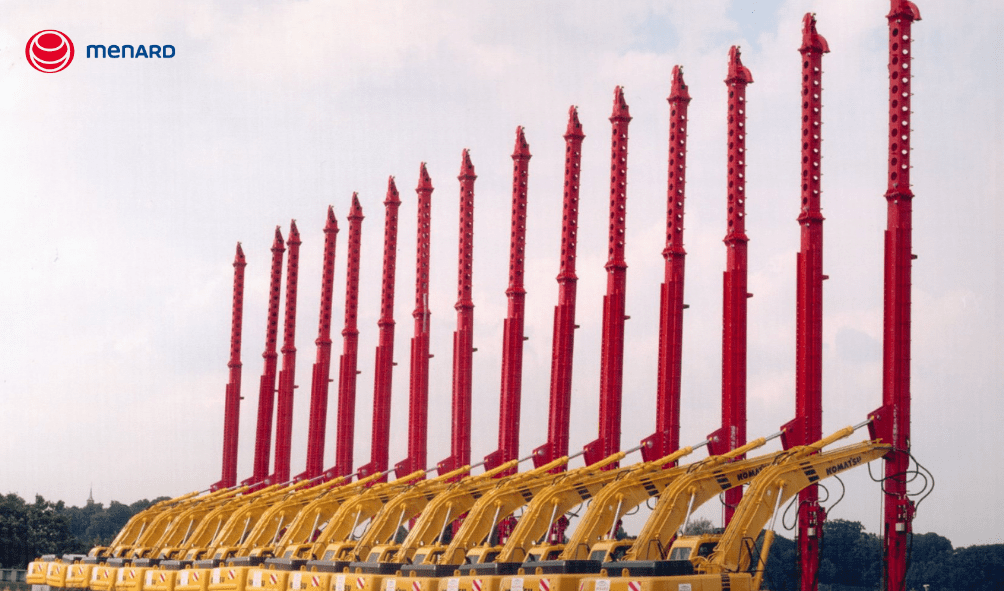

1. Specialized Equipment

We use hydraulic rigs to install the Prefabricated Vertical Drain (PVD) and has considerable experience in penetrating difficult surface layers including predrilling through stiff clays and dense sands. The Prefabricated Vertical Drain (PVD) rigs in Menard Asia have a maximum installation depth of 50 m but this can be extended if required to meet project needs.

Our fleet is engineered to handle tough site conditions, including stiff clays and dense surface layers.

2. Precision Engineering

Menard Asia uses state-of-the-art Prefabricated Vertical Drain (PVD) designed with high water flow capacity, high-resistance filtration properties and durable construction. Menard Asia also has developed its own fleet of PVD installation equipment to meet a wide variety of soil and site conditions.

Each PVD layout is backed by detailed soil studies and advanced modeling. We ensure drain spacing, depth, and performance meet the specific needs of every project.

3. Field-Tested Experience

With hundreds of PVD projects completed across Southeast Asia—including Singapore, Indonesia, Vietnam, Malaysia, and Thailand—Menard Asia is trusted for large-scale ground improvement.

4. Comprehensive Support

From site assessment to design, installation, monitoring, and verification, our in-house teams manage the full process, ensuring quality and consistency at every stage.

Download the PVD Brochure

Want to explore how PVD can accelerate your project timeline?

📩 Download our brochure to learn about:

- Technical specifications

- Application methods and site compatibility

- Case studies from successful ground improvement projects

- Integration with other Menard techniques

Contact Menard Asia for PVD Services

Need help stabilizing soft soils on your site?

📩 Request a Quote for:

- Project-specific consultation

- Site investigation and soil analysis

- Custom PVD design and installation plan

- Detailed cost and time estimates