Jet Grouting (JG) uses high velocity jet of grout to destroy the soil structure and simultaneously mix cement grout into the in-situ soil to form inclusions.

Jet grouting method – is used to improve soil strength parameters and at the same time to create an impervious layer.

Presentation and key elements

This method involves a combination of the following three consecutive processes:

- break-up of the soil structure by a fluid injected into the soil under high pressure;

- extraction of the surplus spoils to the surface;

- mixing of the soil with cement grout, resulting in the cement – and – soil mixture.

The equipment is composed of a grout plant (cement silo, mixing plant, high pressure pump) joined by a flexible high pressure pipe to the drilling rig. The drilling rig is equipped with a special rod that is selected according to the properties of the soil subject to improvement and the expected characteristics of the constructed column (diameter, shape). The injection grout is usually prepared using Portland cement CEM 32.5 or CEM 42.5. The impervious layer can be further improved using bentonite (in case the strength parameters of soil-cement mixture are of secondary importance).

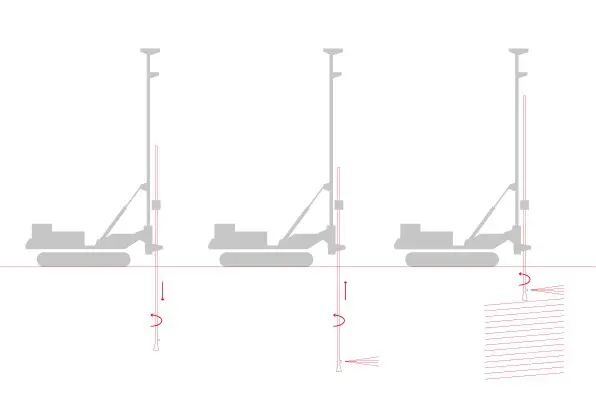

Construction of each column involves the following phases:

- a small diameter guide hole (approximately 10 cm) is drilled down to the design depth;

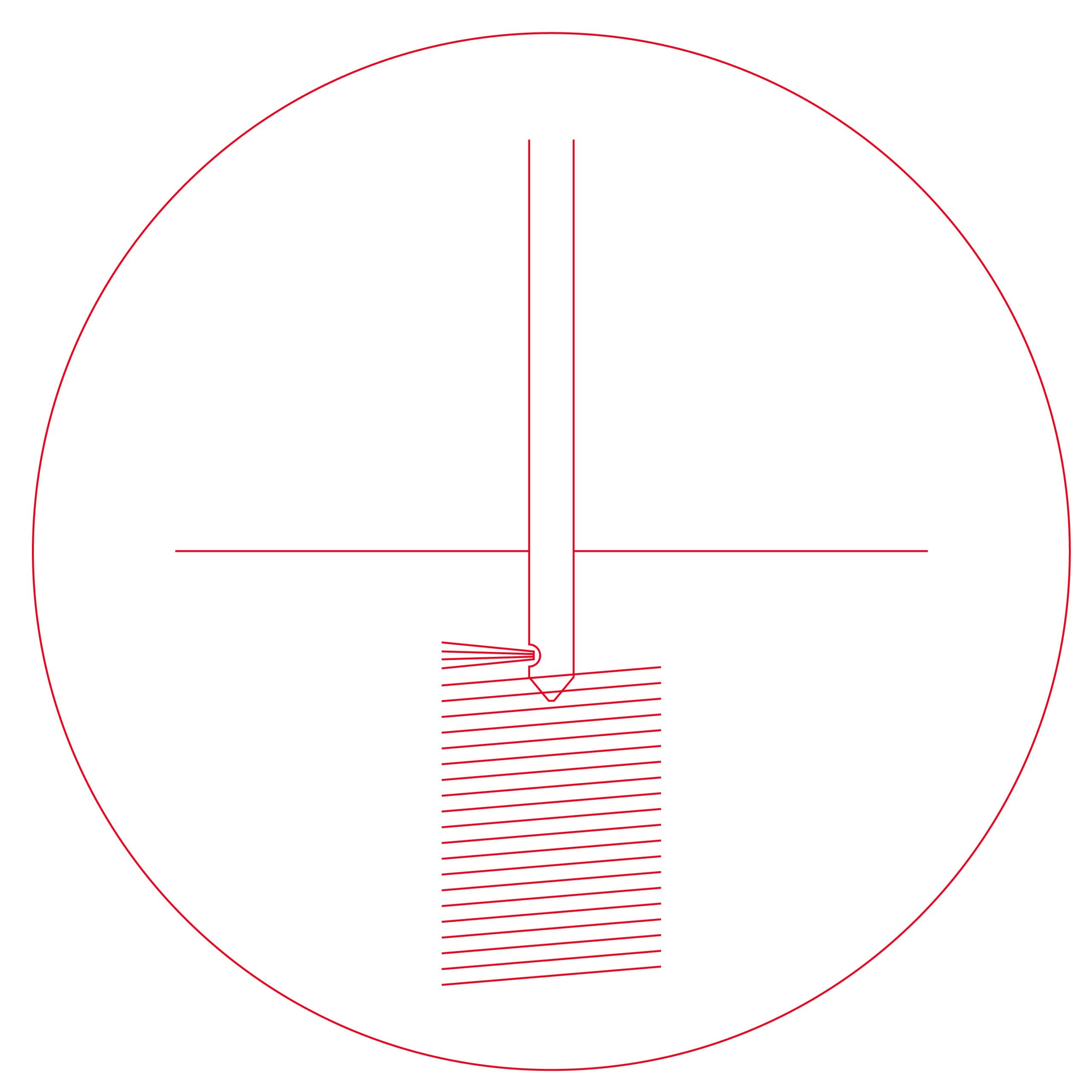

- grout is pumped through the rod at very high flow rate (200 to 400 L/min) and gets out through small diameter injection nozzles (1 to 10 mm in diameter) located at the tip of the drilling rod, thus breaking-up the soil structure and creating soil-cement slurry.

- Column formation by slow withdrawal of the rod. The rod rotates during column formation and does not rotate during panel formation. Spoils need to be regularly removed from the working platform during grouting works.

Single Jet Grouting

The following three different processes take place during grout injection – breaking down the soil phase, removal of spoils under high pressure and grout mixing with the soil.

Double Jet Grouting

In the double Jet Grouting, the air jet surrounds the grout jet in order to increase the efficiency of the injection process. Air-jetting also improves, thanks to an air-lifting effect, the extraction of the spoils along the drilling rod.

Triple Jet Grouting

In the triple Jet Grouting, the soil is loosened by water and air under high pressure. Cement grout is then injected through an independent nozzle into liquefied soil, easily penetrates into it and evenly mixes with the soil particles creating soil-cement slurry.

Jet Grouting can theoretically be used in any type of soft soils, from soft clay to sand and gravel. However, the technique is not suited to coarse gravel or soils with underground water flow. For ground improvement projects, it is typically used under uniform loading (e.g., storage platforms, embankments, slabon-grade) or under localized loads (e.g., building footings, bridge piers).

Jet Grouting can be applied in areas that are difficult to access using inclined columns, directional drilling and mast of different sizes to fit within tight spaces.