Project Overview

In 2009, Menard was contracted to carry out a combination of marine Dynamic Compaction and marine Dynamic Replacement to support some of the caissons of Pasir Panjang Terminal Phase 3 and 4. Menard successfully undertook this scope of works in Design and Built.

Menard’s works in this project consist of:

- Execution of marine Dynamic Compaction and Dynamic Replacement to enhance the properties of the softened clay during dredging more than 30 m below seawater level for the construction of wharf using caisson seawalls.

- Execution of post-testing program by pressuremeter (PMT).

Ground Condition

According to the original design, the soft marine clay at the seabed was to be dredged down to the depth of 30 m below sea level where the shear strength of the stiff clay exceeded 250 kPa. The excavated key was to be then backfilled with sand and compacted using vibro compaction under 3 m of additional overburden sand fill. Next, the surcharge had to be removed, a rubble mound was to be placed over the sand key, and finally caissons were to be sunk onto the mound. While the clay at dredge level was initially very stiff, dredging works and cutting into the clay softened the upper 1 to 1.5 m of the exposed clay surface and post-dredging CPT tests performed before the removal of the overburden sand fill indicated that the clay’s shear strength had dropped to about one third of its original value; i.e. to approximately 80 kPa.

Menard Solution

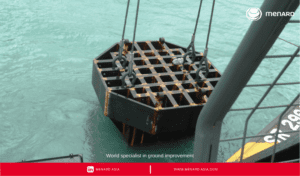

Menard carried out offshore Dynamic Replacement (DR) to improve the softened clay layer. For ease of compaction below water, granite rock was used. The DR rock columns were designed as 2 m diameter columns installed 1.3 m into the softened clay layer followed by a 1.3 m thick of compacted rock mat used as a load transfer platform.

Project Information

Singapore | 2009

Technique: Marine Dynamic Compaction

Application: Port & Airport

Contact one of our experts today!

[contact-form-7 id=”4444″ title=”References Forms”]